Other Applications

Other Applications

The use of resins in other applications: Focus on 3 leading applications

Resins are also used in many other applications, including abrasives, foundries and ablation applications.

In the abrasives sector, resins are used as binders to agglomerate abrasive grains (such as silicon carbide, aluminum oxide or diamond) into a coherent matrix. They give abrasive products a durable structure that maintains the integrity of abrasive grains under force, while allowing uniform wear that continually exposes new cutting grains.

These abrasive products are used, for example, for grinding, polishing and sanding various materials.

In the foundry industry, resins are used in the manufacture of molds and cores because they offer good heat resistance and sufficient rigidity to maintain the precise shape of the mold under high temperatures, thus ensuring the dimensional accuracy of castings.

In addition, resins in foundry molds also provide good peelability, making it easier to remove the casting without damaging the mold or the part.

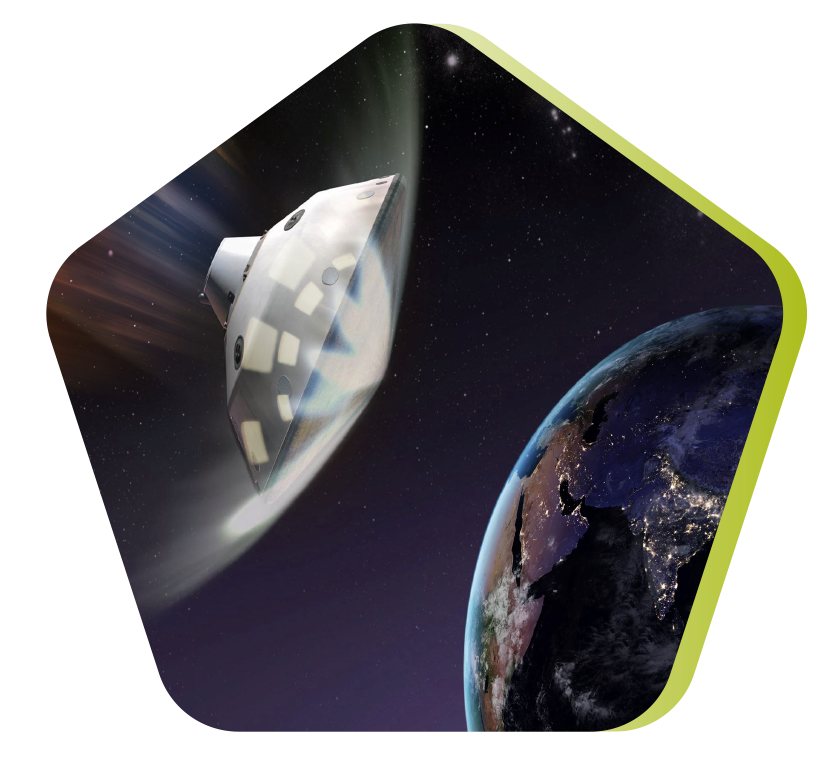

Finally, in certain industries such as Aerospace and Defense, resins are frequently used in ablation composites for their ability to char and form a protective layer that thermally insulates the underlying material, protecting the structure from extreme heat.

These resin-based composites are designed to undergo controlled decomposition, absorbing and dissipating thermal energy without compromising the structural integrity of the protected object.

Why ResiCare for other applications?

With a strong will to research and develop new technologies, ResiCare value its strong expertise in adhesion by extending its technology beyond tires, towards other applications with high added value.

That’s why ResiCare is exploring new markets like ablative materials. Indeed, the ResiCare resin can be used with various fibers to creative ablative composites. The high char yield and thermal performance of the ResiCare resins are key for applications such as heat shields for example. The main difference with historical resin is that we are solving the issues normally arising with formaldehyde-based solutions.

ResiCare is also developing its own technology on insulation materials, thin wheels and 15 others high added value markets!

Based on the client’s requirement, good knowledge of their processes and applications, ResiCare can give them a customized end-to-end solution.

The use of resins in other applications: Focus on 3 leading applications

Resins are also used in many other applications, including abrasives, foundries and ablation applications.

In the abrasives sector, resins are used as binders to agglomerate abrasive grains (such as silicon carbide, aluminum oxide or diamond) into a coherent matrix. They give abrasive products a durable structure that maintains the integrity of abrasive grains under force, while allowing uniform wear that continually exposes new cutting grains.

These abrasive products are used, for example, for grinding, polishing and sanding various materials.

In the foundry industry, resins are used in the manufacture of molds and cores because they offer good heat resistance and sufficient rigidity to maintain the precise shape of the mold under high temperatures, thus ensuring the dimensional accuracy of castings.

In addition, resins in foundry molds also provide good peelability, making it easier to remove the casting without damaging the mold or the part.

Finally, in certain industries such as Aerospace and Defense, resins are frequently used in ablation composites for their ability to char and form a protective layer that thermally insulates the underlying material, protecting the structure from extreme heat.

These resin-based composites are designed to undergo controlled decomposition, absorbing and dissipating thermal energy without compromising the structural integrity of the protected object.

Why ResiCare for other applications?

With a strong will to research and develop new technologies, ResiCare value its strong expertise in adhesion by extending its technology beyond tires, towards other applications with high added value.

That’s why ResiCare is exploring new markets like ablative materials. Indeed, the ResiCare resin can be used with various fibers to creative ablative composites. The high char yield and thermal performance of the ResiCare resins are key for applications such as heat shields for example. The main difference with historical resin is that we are solving the issues normally arising with formaldehyde-based solutions.

ResiCare is also developing its own technology on insulation materials, thin wheels and 15 others high added value markets!

Based on the client’s requirement, good knowledge of their processes and applications, ResiCare can give them a customized end-to-end solution.

All our applications

To build with us the best solution adapted to your needs, let’s get in touch !

To build with us the best solution adapted to your needs, let’s get in touch !