Composite

Composite

The use of resins in composite materials

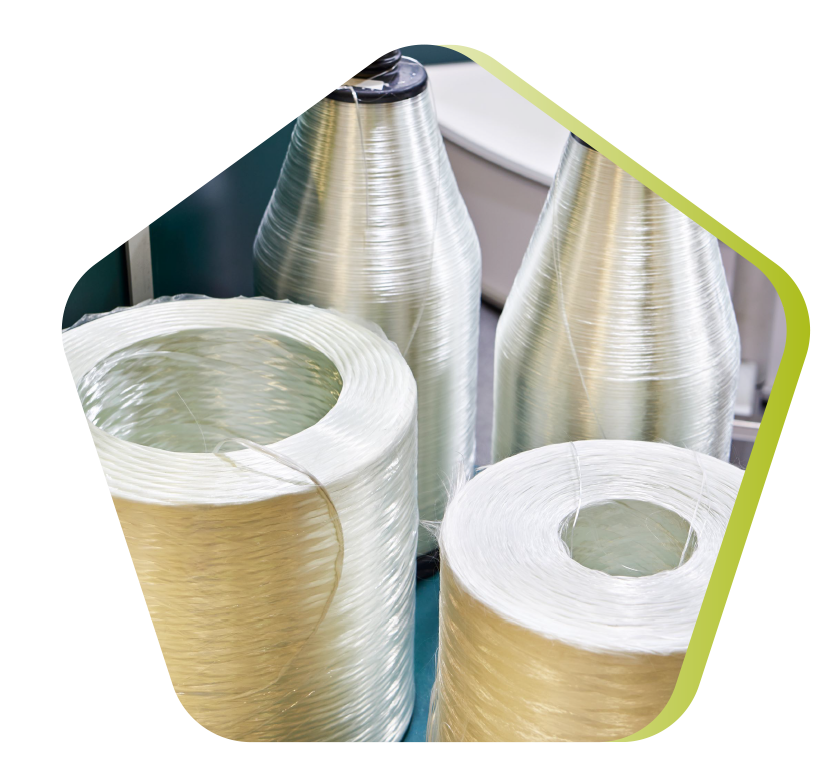

Resins play a crucial role in the manufacture of composite materials: they act as a matrix to bind reinforcements (such as glass, carbon or aramid fibers) and transmit mechanical loads between these reinforcements.

They also give the composite its shape, chemical resistance and insulation properties, while contributing to its overall mechanical strength, durability and performance under various environmental conditions.

They are highly valued by manufacturers because, by varying the type of resin and the resin/fiber ratio, they can tailor composite material properties (such as tensile strength, flexibility or thermal resistance) to the specific requirements of an application.

Why ResiCare for composite?

In order to prepare for a revolution in composite materials, Resicare teams are currently developing new resins without SVHC, without styrene, formaldehyde, bisphenols nor isocyanates.

Our resin can be 100% biobased.

These resins are all plug-and-play with the key composite processes:

- Compression molding

- Contact lamination

- Infusion molding

- Molding of pre-impregnated

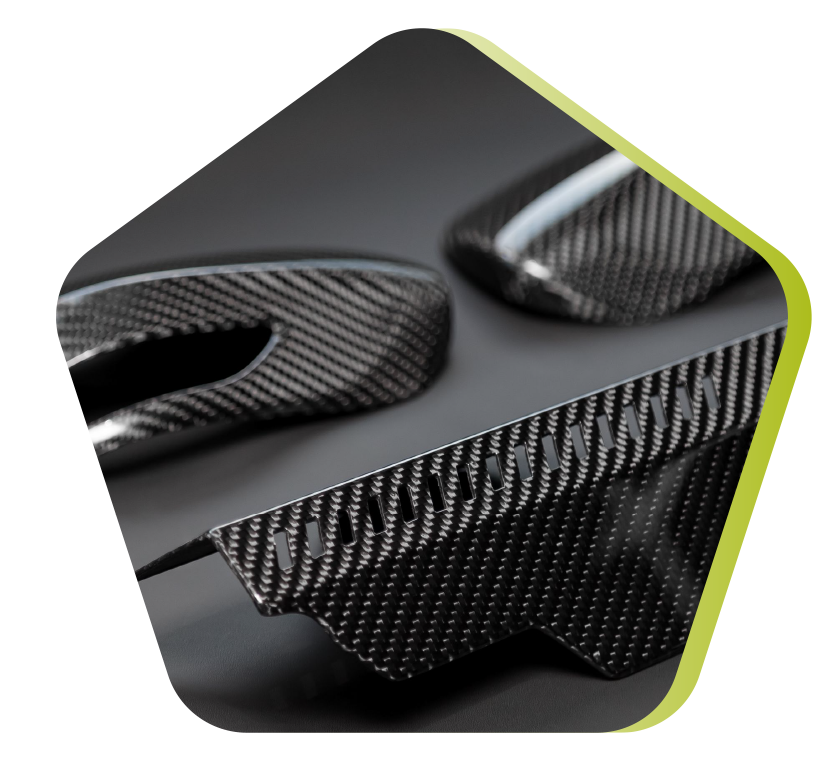

The intrinsic thermal, fire and mecanical resistance properties of our araminolic resin makes it possible to meet the safety and normative requirements of many areas (transportation, automotive, aeronautics, space and defense).

In addition, our possibility of formulating according to a specification makes it possible to meet your requirements.

The use of resins in composite materials

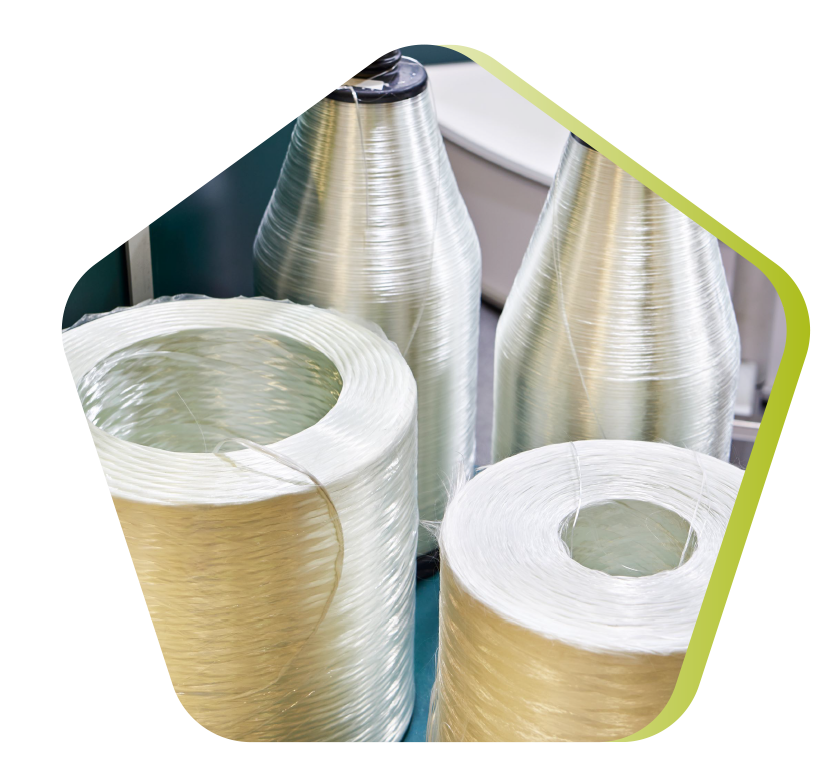

Resins play a crucial role in the manufacture of composite materials: they act as a matrix to bind reinforcements (such as glass, carbon or aramid fibers) and transmit mechanical loads between these reinforcements.

They also give the composite its shape, chemical resistance and insulation properties, while contributing to its overall mechanical strength, durability and performance under various environmental conditions.

They are highly valued by manufacturers because, by varying the type of resin and the resin/fiber ratio, they can tailor composite material properties (such as tensile strength, flexibility or thermal resistance) to the specific requirements of an application.

Why ResiCare for composite?

In order to prepare for a revolution in composite materials, Resicare teams are currently developing new resins without SVHC, without styrene, formaldehyde, bisphenols nor isocyanates.

Our resin can be 100% biobased.

These resins are all plug-and-play with the key composite processes:

- Compression molding

- Contact lamination

- Infusion molding

- Molding of pre-impregnated

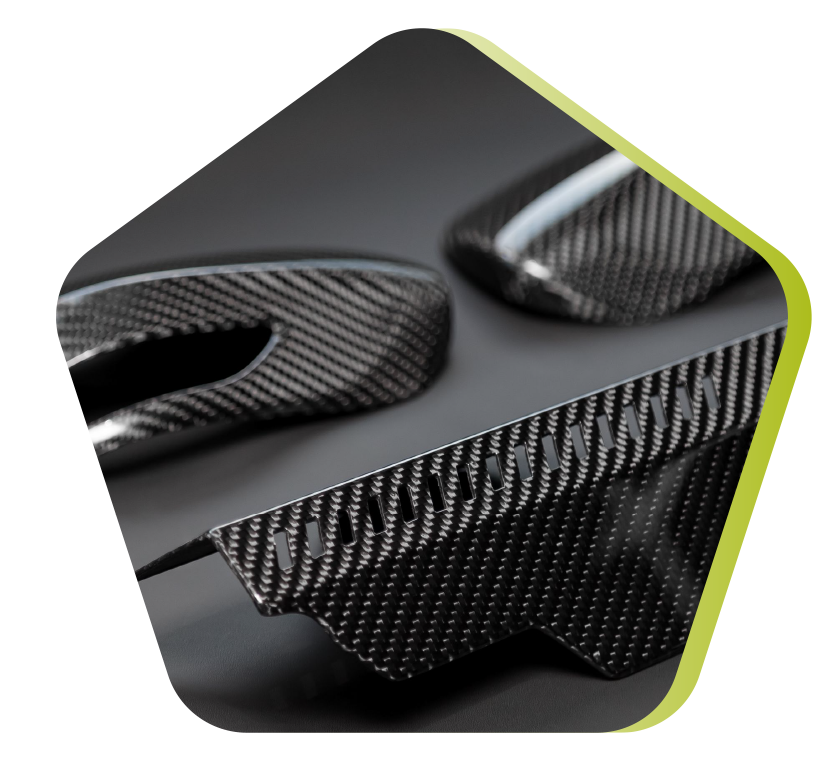

The intrinsic thermal, fire and mecanical resistance properties of our araminolic resin makes it possible to meet the safety and normative requirements of many areas (transportation, automotive, aeronautics, space and defense).

In addition, our possibility of formulating according to a specification makes it possible to meet your requirements.

All our applications

To build with us the best solution adapted to your needs, let’s get in touch !

To build with us the best solution adapted to your needs, let’s get in touch !