Friction

Friction

The use of resins in friction applications

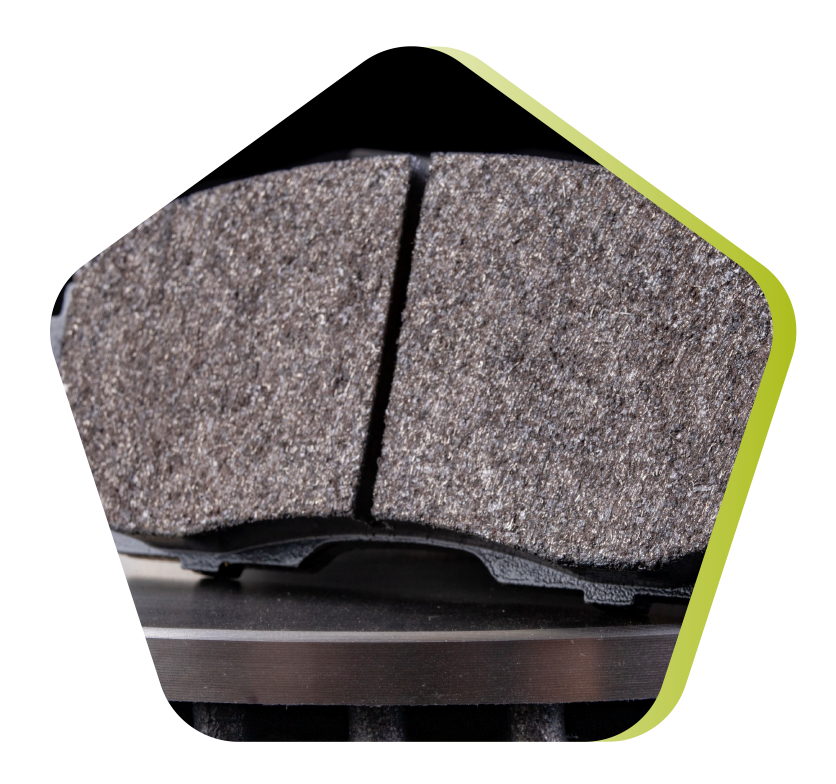

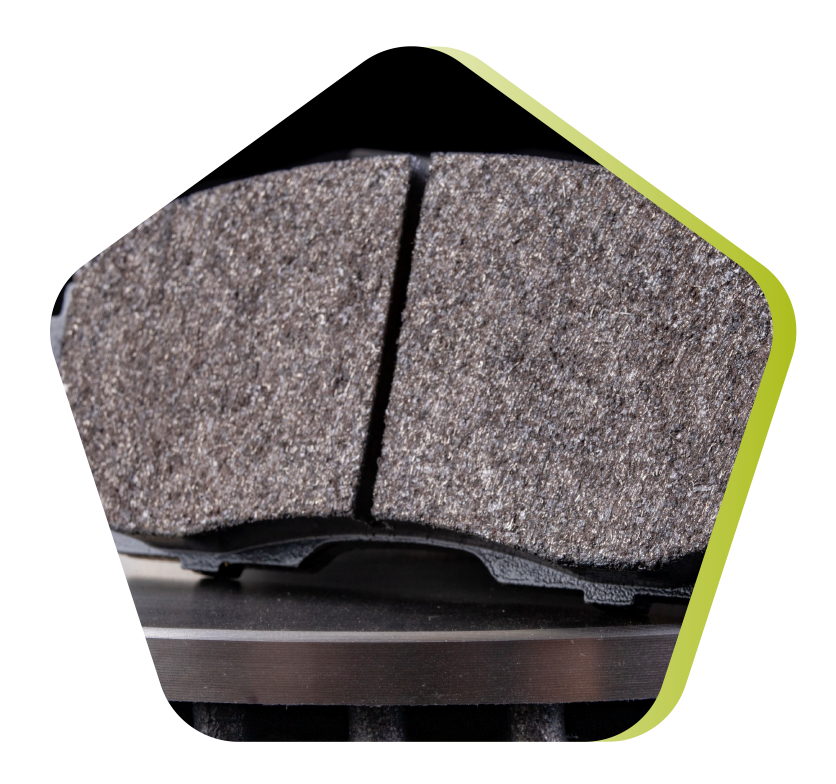

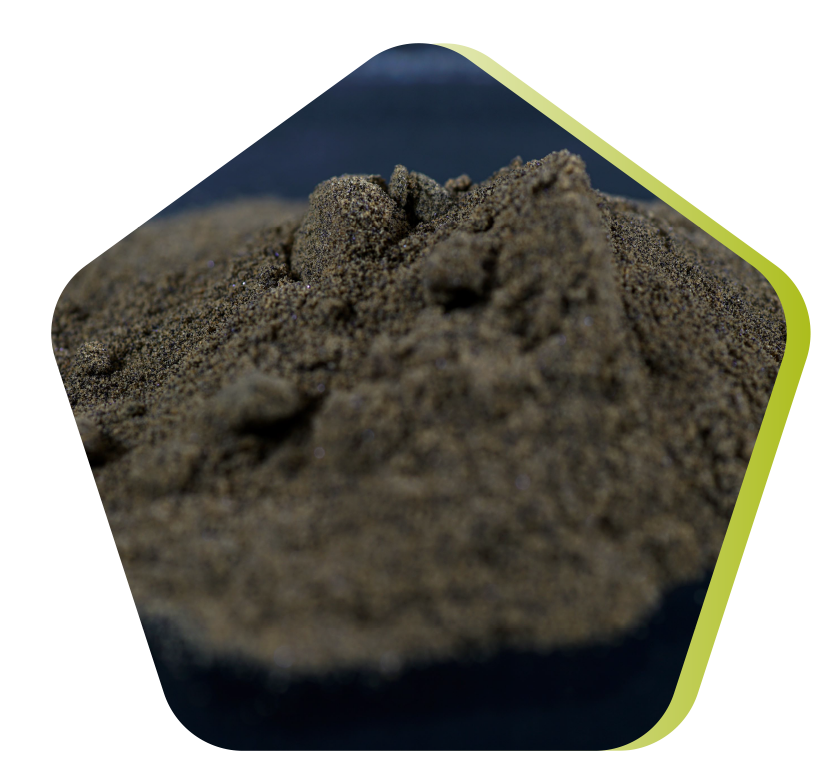

The use of resins in friction applications, such as brake pads, brake linings or clutches, is crucial to the performance, safety and durability of these components.

Resins act as binders in friction composites, bonding the various ingredients together to form a coherent, functional material, enabling friction materials to withstand the high temperatures generated by friction without degrading.

Friction materials wear and produce dust, which can contain harmful substances. This is why developing and using resins that minimize these emissions is a major challenge, improving air quality and reducing the impact on human health.

Why ResiCare for friction?

ResiCare is extending its adhesion expertise in solutions to friction specialty application.

Features: The ResiCare resins are developed to be used in various applications, starting with brake pads, brake linings and clutch facings and multiple markets as automotive, trains, marine, winches, hoists, cranes. With high range of viscocity & PH, high coke rate with powder or waterbased (Dry extract until 70%), it’s compatibility with several additives, without any Formaldyede, resorcinol, phenol, bisphenols and compatible with the main process (impregnation, compression molding..)

Benefits: A unique resin for friction application replacing phenolics one developed according to REACH legislation for workers safety with high performances (modified or unmodified resin for your own specifications). It contributes on Strength & Heat resistance for maintaining stable performance at high temperatures, High coefficient of friction for maximum braking efficiency and Thermal stability for maintaining performance even under heavy braking.

The use of resins in friction applications

The use of resins in friction applications, such as brake pads, brake linings or clutches, is crucial to the performance, safety and durability of these components.

Resins act as binders in friction composites, bonding the various ingredients together to form a coherent, functional material, enabling friction materials to withstand the high temperatures generated by friction without degrading.

Friction materials wear and produce dust, which can contain harmful substances. This is why developing and using resins that minimize these emissions is a major challenge, improving air quality and reducing the impact on human health.

Why ResiCare for friction?

ResiCare is extending its adhesion expertise in solutions to friction specialty application.

Features: The ResiCare resins are developed to be used in various applications, starting with brake pads, brake linings and clutch facings and multiple markets as automotive, trains, marine, winches, hoists, cranes. With high range of viscocity & PH, high coke rate with powder or waterbased (Dry extract until 70%), it’s compatibility with several additives, without any Formaldyede, resorcinol, phenol, bisphenols and compatible with the main process (impregnation, compression molding..)

Benefits: A unique resin for friction application replacing phenolics one developed according to REACH legislation for workers safety with high performances (modified or unmodified resin for your own specifications). It contributes on Strength & Heat resistance for maintaining stable performance at high temperatures, High coefficient of friction for maximum braking efficiency and Thermal stability for maintaining performance even under heavy braking.

All our applications

To build with us the best solution adapted to your needs, let’s get in touch !

To build with us the best solution adapted to your needs, let’s get in touch !